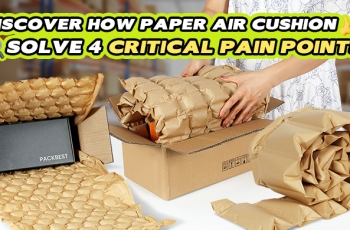

On-Demand Air Pillows: Hype or Real Space Savings?

When considering a switch to air pillow cushioning systems, the big question is: Does on-demand inflation actually save space, or is it just another trend? The short answer? In most cases, yes—it genuinely saves space. But here’s the catch: it only works if the system is set up thoughtfully and the equipment is right for your operation. Let’s break it down. Warehouse Storage: The Uninflated Advantage This is where air pillows cushioning truly shine. Before Inflation: Air pillow film comes in compact rolls, taking up almost 1/10th of the space of the same volume of pre-inflated cushions. A roll can sit on a shelf or under a packing station, barely making a dent in your main storage area. Traditional Materials: Pre-fabricated bubble rolls or foam padding arrive fully expanded. They eat up significant storage space from the moment they enter your warehouse, increasing both storage and inbound freight costs. After Inflation: The magic happens at the moment of packing. Air pillows are created only when needed, meaning you’re never storing empty space. Bottom line: From a storage perspective, storing flat film and inflating on-site is a clear winner. On-Site Packing Space: The Often-Overlooked Factor Saving space in the warehouse is one thing. But what about the packing bench? This is where many operators get tripped up. A material that saves warehouse space doesn’t automatically save space on the floor. Factor Pre-made Bubble Rolls On-Demand Air Pillows Material Storage Bulky rolls Compact film rolls Prep Time Needs to be staged nearby Inflated as needed Workstation Area Can get cluttered with stock Keeps work zones tidy Where it shines: High-SKU, high-velocity environments—think e-commerce fulfillment, 3C electronics, cross-border logistics. The more variable your shipments, the more valuable “just-in-time” cushioning becomes. Where it gets tricky: If you’re running low-volume, highly dispersed packing operations, or if your team can’t…