- 【PackBest Air Packaging】Welcome to PackBest(www.cnpackbest.com)PackBest is Air Packaging!

- Call us 86-136-0004-4028

At PackBest Air Packaging, we know securing your cargo isn’t just about stuffing gaps – it’s about precision, protection, and choosing the right tool for the job. That’s where our PackBest Air Dunnage Bags excel. But simply having air dunnage bags isn’t enough; using them correctly is paramount.

Understanding the Basics

Before we jump into the specifics, it’s crucial to understand what container pallet bags are and why they are essential. These dunnage bags are designed to fill the gaps and voids inside a container, providing stability and protection to your cargo during transit. They act as a cushion, preventing goods from shifting and getting damaged. However, not all container pallet bags are created equal. Different materials offer different benefits, and choosing the right one for your specific needs is vital.

Mastering Air Dunnage Bag Usage:

Your Key to Damage-Free Shipping Using air dunnage bags effectively isn’t rocket science, but overlooking critical steps can be costly. Here’s what you must know:

Measure Your Void Precisely:

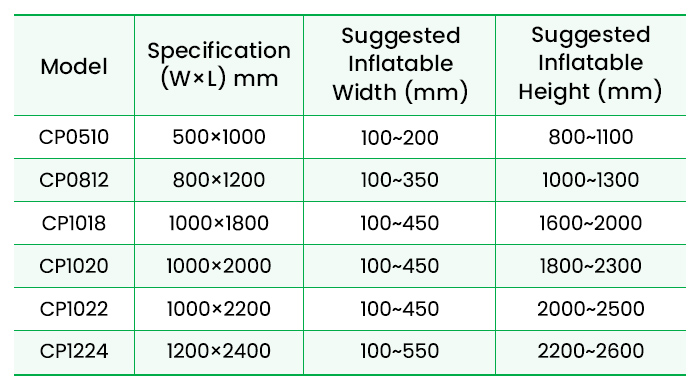

This is non-negotiable. An underfilled bag collapses; an overfilled one risks bursting. Always measure the gap width after the container is 90-95% loaded. PackBest air dunnage bags come in specific sizes – choose the one that matches your measured void exactly.

Prepare the Space:

Clear debris, sharp edges, or protruding nails from the container walls and floor where the air dunnage bag will inflate. A smooth surface is essential for bag integrity. Your cargo’s safety zone starts with a clean deployment area.

Positioning is Protection:

Place the uninflated air dunnage bag centrally within the measured void. Ensure it’s positioned vertically, ready to expand and fill the space uniformly between cargo stacks or against the container wall. Correct placement means uniform pressure distribution.

Furthermore, two critical placement rules must be observed to ensure safety and effectiveness:

Never Stack Dunnage Bags: Dunnage bags must not be stacked either side-by-side (horizontally) or on top of each other (vertically) within the same void space. During transit vibrations and shocks, this stacked configuration significantly increases the risk of “bag shifting” or “bouncing,” compromising their stability and protective function.

Avoid Placement Between Cargo and Container Doors: Under no circumstances should dunnage bags be positioned directly between the cargo and the container doors. When the container is opened, the suddenly released pressure from the inflated bag can violently force the doors open, posing a serious risk of injury to personnel.

Inflation: Slow & Steady Wins:

Connect your inflation device (air compressor or pump) to the dunnage bag’s valve. Inflate gradually until the bag is firm and fills the void completely, but never rock-hard. Over-inflation is the primary cause of bursts! If you’re unsure about the optimal inflation pressure for your dunnage bags, please don’t hesitate to contact our packaging engineers. They will provide precise guidance based on the specific dimensions of your bags.

Seal & Secure Immediately:

Once inflated to the correct pressure, quickly cover the valve securely. A properly sealed dunnage bag maintains pressure for the entire journey.

Never Over-Inflate:

This bears repeating. Firm contact is the goal, not excessive pressure. Think snug fit, not drum-tight. Over-inflation stresses the material and significantly increases rupture risk.

Respect the Bag’s Limits:

Dunnage bags are designed for void fill, not as primary load-bearing structures. Ensure your cargo is properly stacked and blocked before inserting the bag. The bag secures the load; the load must be stable first.

Moreover, it’s necessary to check the condition of the container dunnage bags before use. If there are any damages or defects, they should be replaced in time to avoid affecting the transportation safety of the goods. We strictly control the quality of our products, but it’s still a good habit to check before use, isn’t it?

PackBest offers three distinct dunnage bag solutions engineered from different materials: Kraft Paper Dunnage Bags, PP Woven Dunnage Bags, and PE Dunnage Bags.

Kraft Paper Dunnage Bags: The outer bag is a robust laminate of kraft paper and PP woven fabric, while the inner bag consists of nylon composite material. This construction delivers exceptional burst strength and puncture resistance.

PP Woven Dunnage Bags: It is another excellent option for shippers. Made from woven polypropylene, this bag offers a balance of strength and flexibility. It is more resistant to moisture compared to Kraft paper, making it suitable for a wider range of shipping conditions.

PE Dunnage Bag: Lightweight and cost-effective for non-abrasive cargo. Their flexibility allows easy molding around irregular shapes

Why PackBest?

We’re not just suppliers; we’re partners in your success. With 19+ years in dunnage innovation, our solutions have served for over 5000 clients globally. We tailor every product to solve your unique challenges. Let’s ensure your goods arrive not just intact, but as a testament to your brand’s reliability.

Contact Form

Search

Related News

Hot Tags

Contact Us

Tel:86-136-0004-4028

Email:info@packbest.com

Working Hours:Monday-Saturday,08:00-17:30

© 2026. All Rights Reserved. 粤ICP备2023037612号